|

The gas-over-oil range of pipeline actuators are designed to use pipeline gas as the motive power source. They utilise our robust GH and RH quarter-turn prime movers and are field proven in installations around the world. Control configurations are available to meet virtually any operational requirements.

|

|

Rotork™s ELB (Electronic Line Break) is a robust self-contained electronic pipeline monitoring system designed for use in the gas & oil industry. It will continuously monitor pipeline pressure dynamics to provide early detection of pipeline breaks and initiate automatic valve actuator movement to an emergency position based upon user-defined parameters. The powerful and versatile system can also collect detailed operational data useful for optimising performance and enhancing pipeline safety.

|

|

The HPG range of pipeline actuators are designed to use pipeline gas as the motive power source. They utilise our robust scotch yoke mechanism field proven the world over in all types of fluid power applications. |

|

The Skilmatic range of actuators offer a unique and reliable solution for electric failsafe and modulating control for both quarter-turn and linear valves and dampers. |

|

The RHS enables safe and secure local monitoring and control of Rotork 3rd Generation Skilmatic Range actuators installed in inaccessible locations. |

|

As specialist manufacturers of electro-hydraulic actuation and control equipment we offer comprehensive, purpose designed, engineered and manufactured solutions for the operation of choke and control valves for onshore and offshore installations. |

|

We are well versed with supplying subsea product to meet the harsh conditions and stringent demands of subsea applications. The subsea product range encompasses actuator and gearbox designs for retrievable and non-retrievable applications. Our engineering group works closely with contractor and end-user engineers to meet specific project requirements.

|

|

Designed for marine applications, our VRCS takes into consideration all the challenges faced by ship operators worldwide.

|

|

The Rotork Advanced Valve Remote Control System starts with the self-contained micro power pack E-ACT-C type electro-hydraulic actuator with integral electronic control unit), and goes up to the “I/O Control Cabinet†which contains main and backup communication cards, power distribution, serial interface and a touchscreen panel for local control. |

|

The CQ range provides an innovative fully-concentric and balanced actuator design for quarter-turn valves. The design features a helical mechanism that transforms linear piston motion into quarter-turn valve stem rotation. CQ actuators provide a much higher torque output for a given footprint than scotch yoke designs typically utilised to operate many quarter-turn valve types. It is therefore ideally suited for installation in confined spaces. Further, Rotork’s unique helical pin design provides higher efficiency than a helical gear mechanism utilised by other valve |

|

The Rotork manPOWER range high-integrity failsafe valve operation without the need for any power supply. The self-contained system is suitable for workshop or mounting on a wide range of rotary and linear operated valves and It offers a cost-effective solution for actuator applications where operation is infrequent. Typical applications include emergency shutdown valves and over-or under-pressure protection at remote, unpowered locations.

|

|

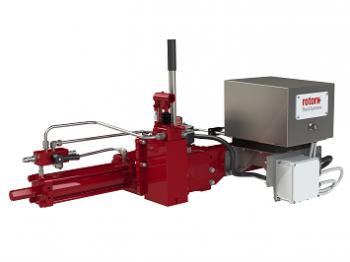

Hydraulic power units (HPU’s) complement our extensive offering of rotary and linear actuators. We have over three decades of experience in their manufacture with units in service in a variety of plants and pipelines in locations spanning the globe. Although our HPU’s are primarily intended to power our hydraulic actuators they are of course suitable for other applications as well. And, in order to provide a complete range of options to best meet the requirements of any application, RFS also has the Skilmatic range of self-contained electro-hydraulic |

|

P/H range production has been discontinued and replaced by GP/GH range. Consult the After Sales department in our Rochester, NY factory for P/H spare parts availability. Phone: +1 585 247 2308 ext. 10459 email: us-asts@rotork.com |

|

PHW range production has been discontinued. Please consult the After Sales department in our Lucca (Italy), factory for PHW spare parts availability or further information. Phone: +3905832221 ext. 520 email:spares.rfs@rotork.com |

|

SVM (Smart Valve Monitor) production is temporarily discontinued. Please consult the Sales department in our Leeds, UK factory for SVM spare parts availability. |

|

Twin Power range production has been discontinued. Please consult the After Sales department in Falun (Sweden) for Twin Power spare parts availability or further information. Phone: +46 23 58700 email: falun.sales@rotork.com

|